What Is Concurrent Engineering

- What Is Concurrent Engineering What Benefits Does It Have

- What Is Concurrent Engineering And Its Benefits

What Is Concurrent Engineering What Benefits Does It Have

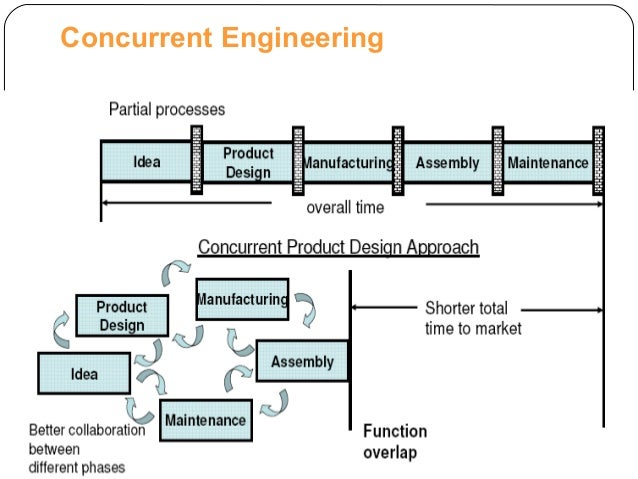

Concurrent design and manufacturing involves simultaneously completing and stages of production. By completing the design and manufacturing stages at the same time, products are produced in less time while lowering cost. Although concurrent design and manufacturing requires extensive communication and coordination between disciplines, the benefits can increase the profit of a business and lead to a sustainable environment for product development.

What Is Concurrent Engineering And Its Benefits

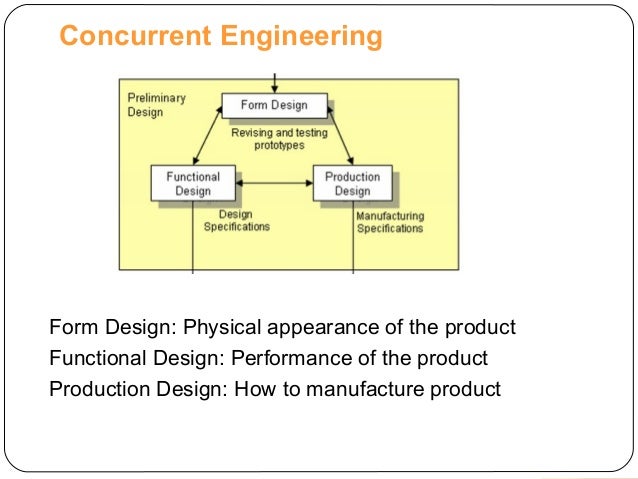

The definition of Concurrent Engineering that we have adopted for the Concurrent Design Facility is: 'Concurrent Engineering (CE) is a systematic approach to integrated product development that emphasises the response to customer expectations.

Concurrent design and manufacturing can lead to a competitive advantage over other businesses as the product maybe produced and marketed in less time. Contents • • • • • • • Introduction [ ] The success behind concurrent design and manufacturing lies within completing processes at the same time while involving all disciplines. As product development has become more cost and time efficient over the years, elements of concurrent engineering have been present in product development approaches. The elements of concurrent engineering that were utilized were cross-functional teams as well as fast time-to-market and considering manufacturing processes when designing. By involving multiple disciplines in decision making and planning, concurrent engineering has made product development more cost and time efficient. The fact that concurrent engineering could result in faster time-to-market is already an important advantage in terms of a competitive edge over other producers. Concurrent engineering has provided a structure and concept for product development that can be implemented for future success.

Comments are closed.